Chapter 1 Basic Definitions and Applications

.jpg)

1.1 Power Strip and Its Basic Functions

A power strip is a device designed to distribute electrical power from a single wall socket to multiple devices simultaneously. It plays an essential role in modern homes, offices, and industrial settings, providing convenience and versatility. Beyond its primary function, a power strip may include features such as surge protection, USB charging ports, and even decorative designs for enhanced usability and aesthetics.

Snippet paragraph: A power strip distributes power to multiple devices, offering convenience and additional features like surge protection and USB ports.

A power strip is not merely a practical tool; it is a staple for those managing multiple devices daily. To fully appreciate its role, it’s important to explore its global terminology and variations.

Global Terminology: What is a Power Strip Called in Different Countries?

Canada

In Canada, the device is most commonly referred to as a "power socket" or "power bar", emphasizing its role in managing electrical connections conveniently.

United States

Power Strip: The term is widely used in the U.S. and highlights its function of providing multiple outlets on a single strip.

Surge Protector: While technically a subset of power strips, this term is used to describe models that include protective components to guard against voltage spikes.

United Kingdom

In the U.K., the device is typically called an "extension lead." The name reflects its purpose: extending the reach of electrical power to areas away from a wall socket. Flexibility and practicality are the hallmarks of this term.

Australia

Australians commonly use the term "power board," which evokes images of reliable and robust power distribution in homes and offices. This term underscores the emphasis on safety and durability.

Bangladesh and Pakistan

In these regions, the device is often referred to as a "multi-plug" or "outlet." This practical naming convention highlights its core functionality: managing multiple connections efficiently.

General Terminology

The term "plug board" is a versatile, catch-all phrase that can refer to any device with multiple sockets. It is often used in regions with diverse linguistic preferences or where multiple naming conventions coexist.

Snippet paragraph: Power strips have unique names globally, such as "power bar" in Canada and "extension lead" in the UK.

Each term reflects cultural and functional priorities, making the device an integral part of daily life worldwide.

1.2 Types of Power Strips and Their Applications

Power strips are not a one-size-fits-all solution. They are designed with various configurations and features to cater to specific needs:

- Standard Power Strips: These are the most basic models, equipped with multiple outlets and typically used for low-power devices such as lamps, chargers, and small appliances.

- Surge-Protecting Power Strips: Designed to protect electronic devices from voltage spikes, these are essential in regions with unstable power supplies or for safeguarding expensive equipment like computers and televisions.

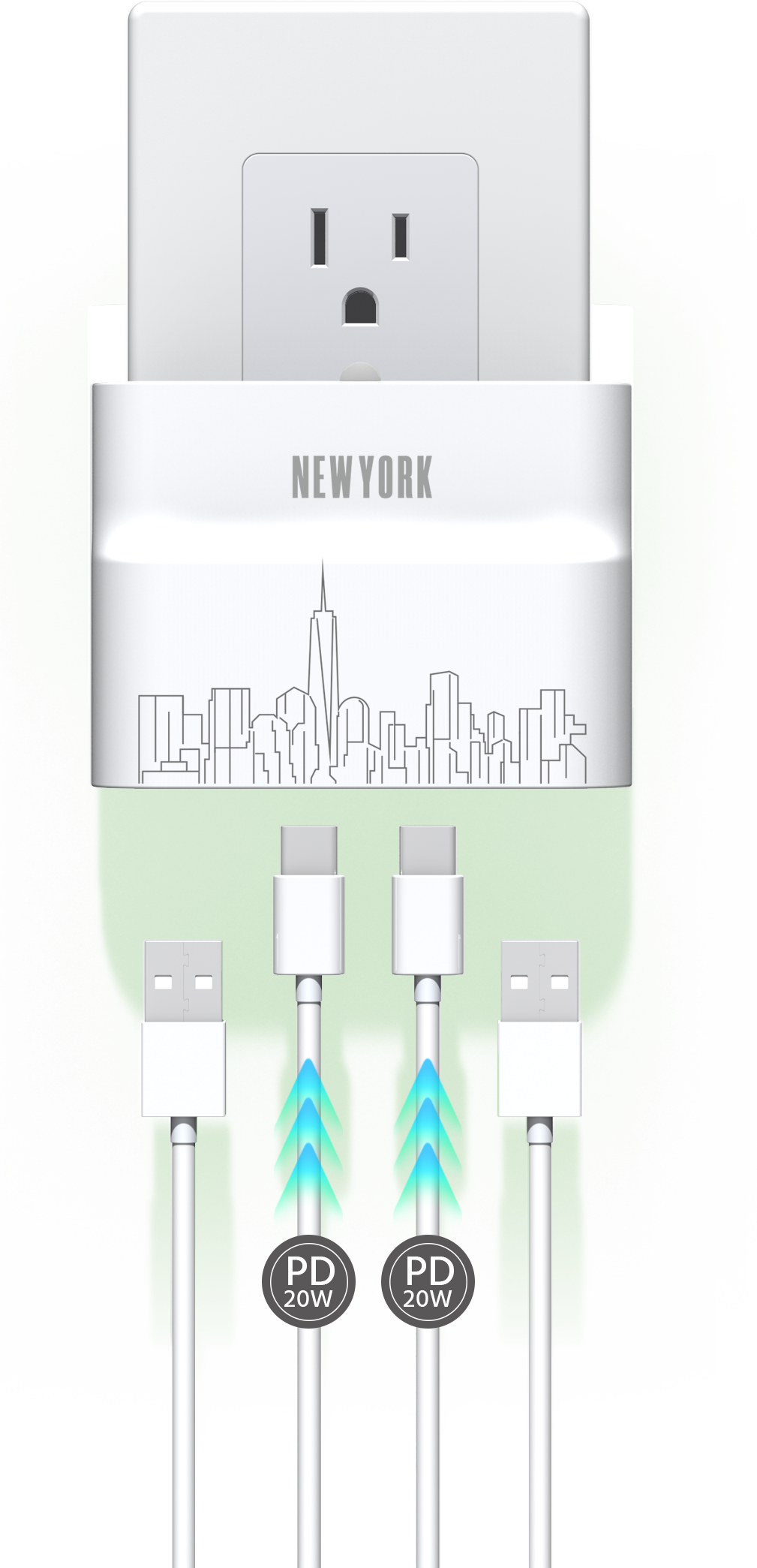

- Travel Power Strips: Compact and lightweight, these models are equipped with universal plug adapters, making them ideal for frequent travelers who need power access in different countries.

- Heavy-Duty Power Strips: Built for industrial or outdoor use, often featuring weatherproofing and higher voltage capacity.

- Decorative Power Strips: Designed with aesthetics in mind, these models integrate seamlessly into modern home decor.

The diversity in power strip types demonstrates their adaptability and relevance across various settings, from homes to offices and beyond.

1.3 Differences Between Power Strips and Surge Protectors

While often used interchangeably, power strips and surge protectors have distinct functionalities:

- Power Strips: Offer multiple outlets for convenience but lack surge protection.

- Surge Protectors: Include built-in surge suppression features, protecting devices from electrical spikes caused by lightning strikes, power outages, or grid fluctuations.

Comparison Table: Power Strips vs. Surge Protectors

| Feature | Power Strip | Surge Protector |

|---|---|---|

| Primary Function | Distribute power to devices | Distribute power and protect devices from surges |

| Surge Protection | No | Yes |

| Use Case | Low-power devices | Sensitive electronics like TVs or PCs |

| Cost | Lower | Higher |

Understanding these differences is critical for selecting the appropriate device for specific needs.

Chapter 2: Technical Specifications

2.1 Key Technical Parameters of Power Strips

Power strips vary in their technical specifications, which determine their suitability for different devices and environments:

- Voltage: Standard models operate at 110-120V (North America) or 220-240V (Europe and Asia).

- Current and Wattage: Most power strips support 10-16A in Asia and Europe and 15A or 20A in North American with a wattage limit of 3680W in Europe, 1875W in North America and 3300W in the Asia.

- Outlet Count: Ranges from 3 to 12 outlets, with some models including USB ports for device charging.

- USB Ports: Increasingly common, with outputs ranging from 5V/3A to 12V/1.5A for fast charging.

Each of these parameters plays a vital role in determining a power strip's functionality and compatibility with various devices.

2.2 Understanding Joule Rating in Surge Protectors

The joule rating indicates a surge protector’s ability to absorb energy from power surges:

- Low Joule Rating (90-270J): Suitable for smaller devices like lamps or clocks.

- High Joule Rating (450-3,600J): Essential for expensive electronics like computers or TVs.

| Joule Rating Range | Recommended Use |

|---|---|

| 90-270 J | Lamps, fans, or basic appliances |

| 450-1000 J | TVs, routers, or small home offices |

| 1000+ J | PCs, gaming consoles, or industrial systems |

A higher joule rating signifies better protection and longer lifespan.

2.3 USB Charging Protocols: QC vs. PD

With the rise of USB ports in power strips, understanding charging protocols like QC (Quick Charge), PD (Power Delivery), and PPS (Programmable Power Supply) is vital. These protocols influence how quickly and efficiently devices can be charged.

- Quick Charge (QC): Developed by Qualcomm, QC is designed for rapid charging of compatible devices by dynamically increasing voltage.

- Voltage Range: 5V, 9V, 12V, or higher.

- Use Case: Ideal for Android smartphones and other QC-compatible gadgets.

- Advantages: Fast, widely adopted, and backward-compatible with standard USB.

- Power Delivery (PD): USB Power Delivery is a universal protocol that allows for higher power levels and flexible voltage adjustments.

- Voltage Range: 5V to 20V.

- Use Case: Designed for laptops, tablets, and smartphones, including Apple devices.

- Advantages: Universal compatibility, bidirectional charging (e.g., powering monitors or laptops).

PPS is a more advanced extension of PD, enabling dynamic adjustment of both voltage and current. This precision minimizes heat and optimizes charging efficiency. - Voltage Range: Adjustable in increments as small as 0.02V.

- Use Case: Found in flagship smartphones like Samsung Galaxy and certain high-end devices.

- Advantages: Faster charging with less heat generation, ideal for battery longevity.

Consumers should consider their device compatibility when choosing USB power strips.

| Charging Protocol | Voltage Range | Use Case | Advantages |

|---|---|---|---|

| QC | 5V, 9V, 12V+ | Android devices | Widely adopted, fast, backward-compatible |

| PD | 5V to 20V | Laptops, tablets, phones | Universal, supports bidirectional power |

| PPS | Adjustable (0.02V) | High-end smartphones | Precise, reduces heat, improves efficiency |

Understanding the technical parameters of power strips, from Joule Ratings to USB charging protocols like QC, PD, and PPS, empowers consumers to make informed choices. These technologies highlight the evolution of power strips into multifunctional, efficient tools for modern life.

Chapter 3: Design and Materials

3.1 Advantages and Disadvantages of Common Materials

The materials used in power strips play a crucial role in determining their durability, safety, and overall performance. Manufacturers commonly use plastics, metals, or a combination of both for power strip enclosures.

-

Plastic (ABS, Polycarbonate)

- Advantages: Lightweight, cost-effective, and resistant to electrical insulation.

- Disadvantages: May not withstand high temperatures or physical impacts as effectively as metal.

-

Metal (Aluminum Alloy)

- Advantages: Excellent heat dissipation and robust protection against physical damage.

- Disadvantages: Heavier, costlier, and may require additional insulation to prevent electrical conductivity.

-

Hybrid Materials:

- Combination of Plastic and Metal: These enclosures use plastic for insulation and metal for added durability and heat management.

| Material | Advantages | Disadvantages |

|---|---|---|

| Plastic (ABS) | Lightweight, affordable, insulating | Less durable, lower heat resistance |

| Metal (Aluminum) | Durable, heat dissipating | Heavy, expensive, conductive |

| Hybrid | Balanced durability and safety | Can be more expensive |

Snippet paragraph: Power strip enclosures are commonly made from plastic, metal, or hybrid materials, each with distinct pros and cons.

Choosing the right material depends on the intended use, balancing factors like cost, safety, and durability.

3.2 Outlet Layout and Spacing Design

The socket layout and spacing are vital aspects of power strip design, directly impacting usability and functionality.

Key Considerations:

-

Socket Spacing:

- Standard Spacing: Suitable for small plugs but may not accommodate larger adapters.

- Wide Spacing: Designed for bulkier plugs, preventing overcrowding.

-

Orientation:

- Horizontal Layout: Ideal for desks or workstations, offering easy access to sockets.

- Vertical Layout: Space-saving and commonly used for wall-mounted power strips.

-

Angled Sockets:

- 45-Degree or 90-Degree Angles: Prevent cord overlap, especially useful in tight spaces.

| Layout Type | Features | Best Use Case |

|---|---|---|

| Standard Spacing | Fits small plugs | General household use |

| Wide Spacing | Accommodates bulky adapters | Home offices, entertainment systems |

| Vertical Layout | Space-saving, wall-mounted | Small rooms, kitchens |

Snippet paragraph: Socket spacing, orientation, and angles are critical design factors affecting power strip usability.

The spacing between outlets on a power strip plays a crucial role in both functionality and safety. In the early days, a standard socket spacing of 28mm was common across many power strip designs. This spacing worked for many of the devices at the time, but as technology advanced, so did the size and variety of plugs. Over the years, we noticed that larger power adapters and bulky plugs were difficult to fit into these narrower spaces without blocking adjacent outlets.

To address this issue and improve the user experience, we decided to increase the socket spacing from 28mm to 39mm. This adjustment wasn’t just about accommodating larger plugs—it was also a response to evolving customer feedback. Users were frustrated by the lack of flexibility in using multiple plugs simultaneously, especially when they needed to power devices like laptops, game consoles, or printers, which often have bulky chargers or adapters. By expanding the space between outlets, we’ve made it easier for customers to plug in and use more devices without wasting outlets or dealing with cumbersome adapters.

This change reflects our ongoing commitment to both function and innovation. It ensures that our power strips are versatile enough to handle a wider range of modern devices, without compromising on safety or performance.

By optimizing socket design, manufacturers can enhance convenience and reduce frustration for users managing multiple devices.

3.3 Child Safety Features: The Role of Protection Shutters

Child safety is a key consideration in power strip design, particularly in households with young children. The child safety shutter is a built-in feature that blocks access to electrical contacts, preventing accidental electric shocks.

Child protection shutters are built-in safety mechanisms that block access to live electrical contacts, reducing the risk of electric shock. These shutters only open when equal pressure is applied to both prongs of a plug, ensuring safety without compromising functionality.

How It Works:

- Spring-Loaded Mechanism: The shutter remains closed until equal pressure is applied to both prongs of a plug.

- Plastic Barriers: These block access to sockets when not in use, creating a physical barrier against small objects like fingers or toys.

- Tamper-Resistant Design: Meets international safety standards, reducing the risk of electrical accidents.

Importance of Child Safety Shutters:

- Prevents Accidents: Essential for homes with children, reducing the risk of electric shocks.

- Meets Certification Standards: Required for compliance with certifications like CE, ETL, or UL.

- Added Peace of Mind: Provides reassurance for parents and caregivers.

Snippet paragraph: Child safety shutters block access to electrical contacts, preventing accidents and meeting international safety standards.

Dive Deeper: The Intersection of Design, Safety, and Aesthetics

Power strips have evolved from simple functional tools to well-designed products that enhance safety and aesthetics.

The Role of Design in Safety:

- Heat Dissipation: Metal enclosures and vented designs prevent overheating, improving safety.

- Indicator Lights: Clearly display the status of surge protection and power availability.

- Durability Features: Reinforced materials withstand wear and tear, ensuring long-term reliability.

Aesthetics and User Appeal:

- Minimalist Designs: Power strips with sleek, modern looks blend seamlessly with home or office décor.

- Color Options: White, black, or even customizable colors cater to diverse preferences.

- Integrated Cable Management: Reduces clutter, keeping spaces neat and organized.

| Feature | Functional Benefit | Aesthetic Appeal |

|---|---|---|

| Vented Metal Enclosures | Prevent overheating | Industrial, modern look |

| Minimalist Appearance | Space-saving and subtle | Blends with décor |

| Cable Management | Reduces clutter | Clean and organized spaces |

By combining thoughtful design, robust materials, and innovative features like child safety shutters, modern power strips cater to safety, functionality, and style.

Chapter 4: Functional Features

4.1 Intelligent IC Technology and Its Role in USB Charging

Intelligent IC (Integrated Circuit) technology detects the connected device and delivers the optimal charging current. This prevents overcharging, extends battery life, and ensures efficient power usage. Intelligent IC technology enables faster, safer, and more efficient charging for smartphones, tablets, and other USB devices.

Intelligent IC technology automatically recognizes the power requirements of each device connected to a USB port. It adjusts the current flow to maximize charging speed while avoiding overloading or overheating.

Benefits of Intelligent IC Technology:

| Feature | Benefits |

|---|---|

| Device Detection | Prevents overcharging or undercharging, prolonging battery life. |

| Optimized Power Delivery | Reduces charging time without sacrificing safety. |

| Enhanced Compatibility | Supports a wide range of devices, from smartphones to wearable tech. |

4.2 Surge Protection: Key Features and Benefits

Surge protection shields devices from voltage spikes, preventing damage to sensitive electronics. It is particularly important for areas prone to lightning or unstable power supplies.

Why Is Surge Protection Essential?

Voltage surges can destroy sensitive components in electronics, especially in devices like computers, TVs, and home appliances. Surge-protected power strips include built-in components, such as MOVs (Metal Oxide Varistors), to absorb and divert excess electricity safely.

Key Surge Protection Features to Look For:

| Feature | Importance |

|---|---|

| Joule Rating | Indicates how much energy the surge protector can absorb. Higher ratings are better. |

| Clamping Voltage | The voltage level at which the surge protector activates. Lower is better. |

| Response Time | How quickly the device responds to a surge. Faster response times are safer. |

4.3 Design Features: RGB Lighting and Consumer Appeal

Modern power strips are no longer designed just for utility. With features like RGB lighting and decorative casings, they cater to style-conscious users who prioritize aesthetics in their living or working spaces.

RGB lighting enhances the visual appeal of power strips, making them attractive for gaming setups and modern workspaces. Such design elements cater to younger, tech-savvy consumers seeking stylish yet functional devices.

Power strips are often visible on desks, countertops, and floors, making their design an essential consideration. Manufacturers now offer products with sleek finishes, adjustable lighting, and unique form factors to appeal to modern tastes.

Popular Aesthetic Features in Power Strips:

| Feature | Functionality/Benefit |

|---|---|

| RGB Lighting | Allows users to customize colors to match room decor or mood. |

| Compact Designs | Minimizes clutter and improves portability. |

| Hidden Cable Storage | Keeps wires organized and reduces visual distractions. |

The Appeal of Advanced Features

Leading Paragraph

Functional features like smart charging, surge protection, and aesthetic design elements increase the value of power strips for targeted customer groups, including tech-savvy individuals, gamers, and businesses.

Snippet Paragraph

Power strips with advanced features cater to diverse needs, from safety to style and efficiency.

Dive Deeper

How Functional Features Meet Consumer Needs

Consumers today expect more from their power strips. By combining technical innovation with user-centric design, manufacturers are able to meet the demands of various markets.

Top Customer Priorities:

| Customer Group | Feature Priorities |

|---|---|

| Tech Enthusiasts | Intelligent IC technology, USB-C compatibility, surge protection. |

| Gamers | RGB lighting, hidden cable storage, high wattage capacity. |

| Business Professionals | Compact designs, reliable surge protection, CE/UL/ETL certifications. |

Modern power strips are more than electrical tools; they are solutions tailored to safety, functionality, and design. By understanding features like intelligent IC technology, surge protection, and aesthetic elements, consumers can choose products that fit their needs and lifestyle.

Chapter 5: Safety Certifications

5.1 Key International Certifications for Power Strips

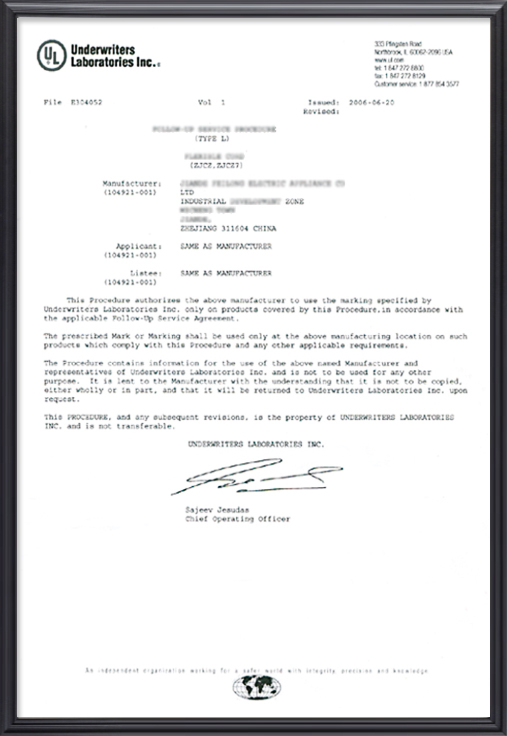

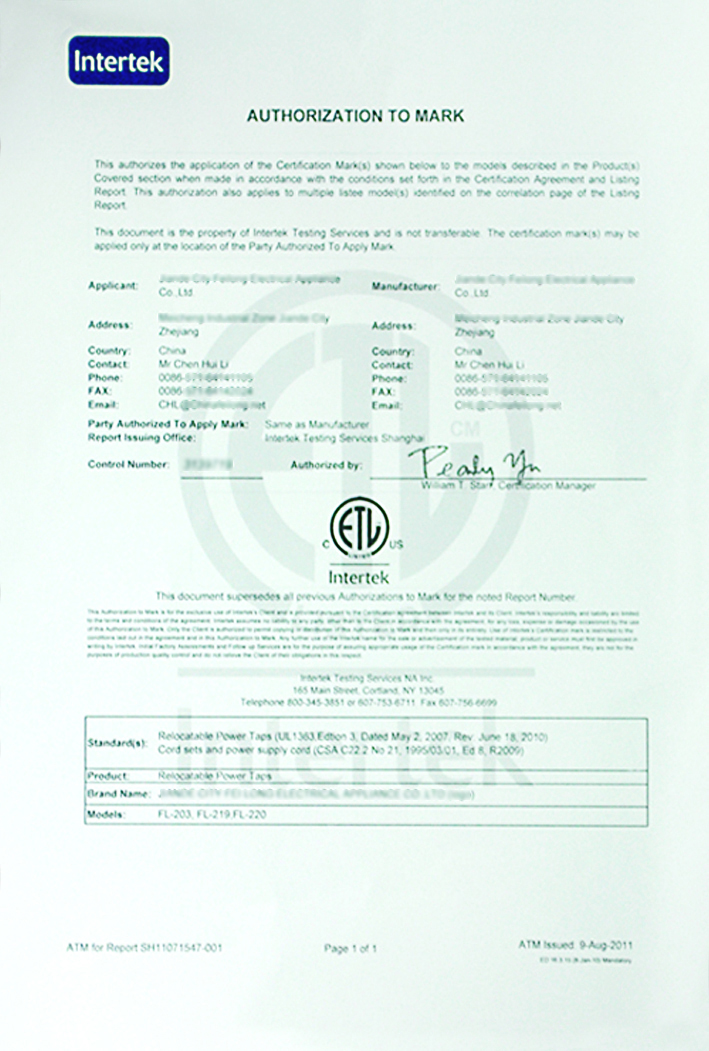

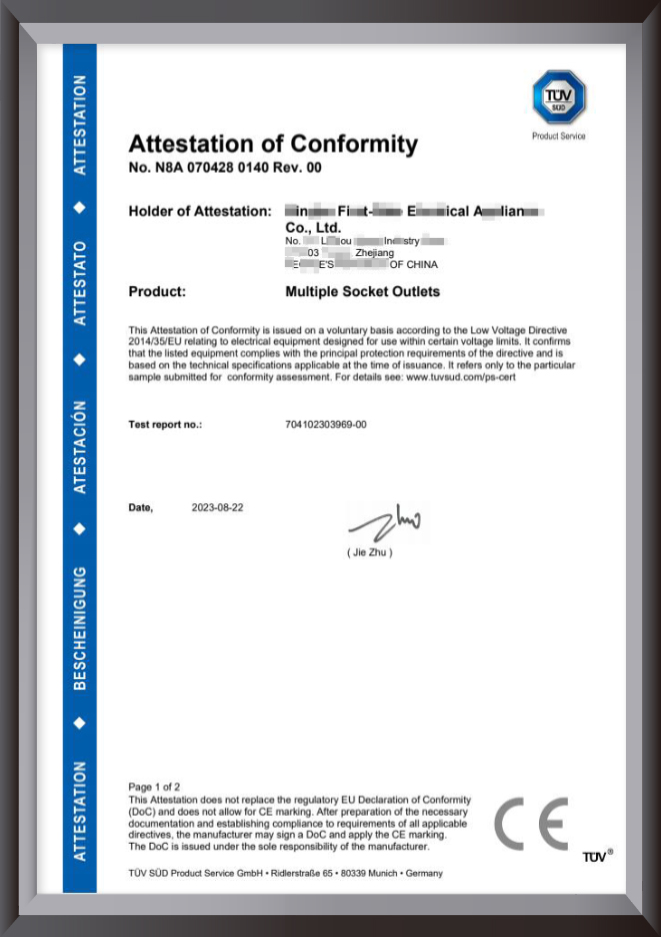

Safety certifications are critical for ensuring that power strips meet global standards for performance, durability, and safety. Among these, UL (Underwriters Laboratories) and ETL (Electrical Testing Laboratories) are widely recognized in North America, while the CE (Conformité Européenne) and GS (Geprüfte Sicherheit) is essential for products sold in Europe.

These certifications not only signify that a product has undergone rigorous testing but also serve as a symbol of reliability for consumers and businesses. In this chapter, we will explore the significance of UL, ETL, GS, and CE certifications, their respective testing processes, and why these marks matter for both manufacturers and end users.

What Is UL?

Background on UL

Founded in 1894, Underwriters Laboratories (UL) is a globally recognized safety organization that develops standards and conducts testing to ensure product safety. UL's primary goal is to prevent accidents and promote safe living environments.

Mission and Scope

UL certifications span a wide range of products, from household appliances to industrial equipment. For power strips, UL certification ensures protection against hazards like fire, electrical shocks, and overheating.

What Is ETL?

Background on ETL

Electrical Testing Laboratories (ETL), established by Thomas Edison in 1896, is another trusted name in product certification. Like UL, ETL tests and certifies products to ensure they meet established safety standards.

Mission and Scope

ETL focuses on providing manufacturers with an efficient path to compliance without compromising on safety. Power strips bearing the ETL mark meet rigorous benchmarks equivalent to those certified by UL.

What Is CE?

Background on CE

The CE (Conformité Européenne) mark is a mandatory certification for products sold within the European Economic Area (EEA). Unlike UL and ETL, which focus on North American standards, CE certification ensures that a product complies with European health, safety, and environmental standards.

Mission and Scope

CE certification acts as a "passport" for products entering the European market. It covers a wide range of categories, including electrical equipment like power strips. Manufacturers must conduct detailed assessments to ensure compliance, ranging from product testing to risk evaluations.

What Is GS?

Background on GS Certification

GS (Geprüfte Sicherheit) is a product safety certification mark primarily used in Germany and other European markets. The certification is issued by authorized testing bodies in Germany, following the requirements set out by the German Product Safety Act (ProdSG). The GS mark signifies that a product has been tested for safety and is compliant with the strict safety standards established by German law.

The GS mark is highly respected in Europe, representing a commitment to quality and safety. For electrical products like power strips, the GS mark ensures the product has undergone comprehensive testing for electrical hazards, fire protection, and overall reliability. It also means that the product adheres to the safety guidelines set by Germany’s regulatory authorities, which are often regarded as some of the most stringent in the world.

Mission and Scope

The GS certification scheme covers a wide array of consumer products, focusing on ensuring safe usage for both consumers and businesses. Its mission is to provide consumers with the confidence that the products they purchase are safe to use, particularly in areas where electrical safety is a concern.

For power strips, obtaining the GS certification means that the product has passed rigorous safety tests, including electrical hazard checks, grounding assessments, and fire safety evaluations. This certification plays a crucial role in boosting consumer confidence, particularly in the European market, by ensuring that power strips meet high standards for safety, durability, and performance.

UL Standards for Power Strips

UL 1363 Standard

For power strips, the UL 1363 Standard applies specifically to relocatable power taps, ensuring safety in both residential and commercial use.

Key Safety Tests

Power strips certified under UL 1363 must pass:

- Impact Resistance Tests: Ensures the casing can withstand physical shocks.

- Fire Hazard Tests: Verifies that the product resists overheating and fire.

- Electrical Shock Tests: Confirms that users are protected from live parts.

ETL Standards for Power Strips

Certification Process

ETL certification involves a similar process to UL but is often chosen by manufacturers for its faster and more cost-effective testing timelines.

Key Safety Tests

ETL-certified power strips must pass:

- Mechanical Durability Tests: Ensures structural integrity.

- Thermal Resistance Tests: Verifies the ability to handle high temperatures.

- Electrical Performance Tests: Confirms consistent and safe electrical flow.

Certification Mark

The ETL Mark indicates compliance with North American safety standards. Each mark includes a unique control number for verification.

CE Standards for Power Strips

Certification Process

To obtain the CE mark, manufacturers must:

- Conduct a Risk Assessment: Evaluate potential hazards of the product.

- Perform Conformity Testing: Ensure compliance with applicable directives, such as the Low Voltage Directive (LVD) and the Electromagnetic Compatibility (EMC) directive.

- Maintain a Technical File: Document all testing, materials, and compliance reports.

Key Safety Tests

The CE mark certifies compliance with:

- Electrical Safety Standards: Ensures safe operation under normal and fault conditions.

- Environmental Standards: Verifies eco-friendly materials and processes.

- EMC Standards: Ensures the product doesn’t interfere with other electronic devices.

Why Certifications Matter

Safety Assurance

All three certifications—UL, ETL, and CE—serve as a guarantee that power strips are designed and tested to prevent electrical hazards, such as short circuits and voltage spikes.

Compliance with Regional Standards

- UL and ETL are essential for North America.

- CE is mandatory for the European market.

These certifications ensure compliance with local safety and environmental regulations, facilitating global trade.

Consumer Confidence

Certified power strips instill trust among consumers, who can rely on the products to perform safely and consistently. For manufacturers, these certifications open doors to major retailers and ensure a competitive edge.

How to Identify Certified Power Strips

Label Components

Certified power strips include clear labels with the following:

- Logos: UL, ETL, GS or CE marks.

- Certification Numbers: Unique identifiers for verification.

- Safety Ratings: Details like maximum voltage and amperage.

Verifying Authenticity

Consumers should always verify certification numbers on official websites, such as:

- UL Database: https://www.ul.com/

- ETL Verification: https://www.intertek.com/etl/

Safety certifications like UL, ETL, GS, and CE are critical for ensuring power strips meet global safety standards. By understanding these certifications, consumers can make informed decisions and prioritize safety, reliability, and compliance.

Chapter 6: Production and Cost Optimization

Power strips are ubiquitous in homes and workplaces, but behind every unit lies a complex production process that balances quality and cost. Understanding this process is crucial for manufacturers to remain competitive while meeting customer expectations.

Snippet paragraph: Power strip production requires efficient processes, quality control, and cost optimization to meet market demands and ensure safety.

The manufacturing of power strips involves meticulous planning, from sourcing materials to final assembly, with a constant focus on minimizing costs without compromising safety or functionality.

6.1 Power Strip Production Process

To create a reliable power strip, manufacturers follow a multi-step process:

- Sourcing Materials: High-quality plastic, copper wiring, and other components are procured based on safety and durability standards.

- PCB Assembly: The printed circuit board (PCB), which controls power distribution, is assembled and tested.

- Casing Design: The outer casing is molded using materials such as ABS or polycarbonate, ensuring both durability and aesthetic appeal.

- Assembly: Components are integrated into the casing, with strict adherence to safety protocols.

- Quality Testing: Each unit undergoes rigorous testing to meet certification standards like UL, ETL, or CE.

- Packaging: Finished products are packaged with branding and safety instructions before distribution.

Table: Key Stages in Power Strip Production

| Stage | Key Activities | Importance |

|---|---|---|

| Sourcing Materials | Procuring wires, casing, PCBs | Ensures safety and functionality |

| PCB Assembly | Designing and testing circuit boards | Controls power flow and surge protection |

| Casing Design | Molding durable and safe exteriors | Protects components and users |

| Assembly | Integrating components and wiring | Creates the final product |

| Quality Testing | Conducting safety and performance tests | Meets certification requirements |

| Packaging | Branding and safety labeling | Prepares product for market |

6.2 Cost Breakdown of Components

- Components: Copper wires, sockets, and circuit boards make up a significant portion of expenses.

- Labor: Skilled workers are required for assembly and quality assurance.

- Certifications: Obtaining safety certifications like UL and CE incurs upfront costs but ensures marketability.

- Packaging: Branding and eco-friendly packaging materials add to the total cost.

| Component | Percentage of Total Cost | |

|---|---|---|

| Raw Materials | 40-50% | Wires, PCBs, casing materials |

| Labor | 20-30% | Skilled assembly and testing |

| Certifications | 10-15% | UL, ETL, or CE certification fees |

| Packaging and Branding | 5-10% | Eco-friendly and aesthetic designs |

6.3 Strategies for Reducing Production Costs

Manufacturers use various strategies to reduce costs without compromising quality:

- Bulk Purchasing: Buying materials in large quantities reduces per-unit costs.

- Automation: Introducing automation in assembly lines minimizes labor costs and improves efficiency.

- Simplified Designs: Streamlining product designs reduces material usage and production complexity.

- Outsourcing: Partnering with specialized suppliers for specific components can lower expenses.

- Energy Efficiency: Using energy-efficient production methods reduces operational costs.

Strategies for Cost Optimization

Manufacturers use various strategies to reduce costs without compromising quality:

- Bulk Purchasing: Buying materials in large quantities reduces per-unit costs.

- Automation: Introducing automation in assembly lines minimizes labor costs and improves efficiency.

- Simplified Designs: Streamlining product designs reduces material usage and production complexity.

- Outsourcing: Partnering with specialized suppliers for specific components can lower expenses.

- Energy Efficiency: Using energy-efficient production methods reduces operational costs.

Balancing Quality and Cost

While cost reduction is essential, maintaining product quality is non-negotiable. Compromising on quality can lead to safety hazards, failed certifications, and loss of consumer trust. Key approaches include:

- Investing in Certifications: UL and CE certifications build consumer confidence and justify premium pricing.

- Testing Protocols: Stringent quality control ensures products meet safety and performance standards.

- Sustainability: Using recyclable materials and energy-efficient production methods can attract eco-conscious customers.

Optimizing production and costs is a delicate balancing act that requires careful planning and innovation. By streamlining processes, investing in automation, and prioritizing quality, manufacturers can remain competitive in an evolving market. As sustainability and efficiency become more critical, embracing future trends will ensure long-term success in the power strip industry.

Chapter 7: Common Questions and Best Practices

The effective and safe use of power strips often raises questions, especially for those seeking to maximize both functionality and longevity. In this chapter, we explore common concerns, provide solutions, and share best practices for maintaining an organized and efficient setup.

7.1 Why Do Surge Protector Lights Flicker?

One of the most frequently asked questions is about the indicator lights on surge protectors. These lights play a critical role in signaling the status of the device’s surge protection capabilities.

- Reason for Flickering Lights: A flickering light typically means that the surge protector’s internal components, such as metal oxide varistors (MOVs), have reached their absorption limit. Surge protectors are designed to "sacrifice" themselves by absorbing excess voltage, protecting connected devices. When the lights flicker or go out entirely, it’s often a sign that the surge protector is no longer effective and should be replaced.

- Action Steps: If you notice flickering lights:

- Unplug the surge protector immediately.

- Replace it with a certified model, ensuring it meets safety standards like UL or ETL.

7.2 Best Practices for Long-Term Use

Ensuring the longevity and safety of power strips requires careful attention to usage habits. Here are some essential practices:

-

Avoid Overloading the Power Strip:

- Never connect devices that exceed the strip’s maximum wattage or amperage rating.

- Overloading can lead to overheating, fire hazards, and device damage.

-

Inspect for Wear or Damage:

- Regularly check the casing, wires, and plugs for signs of wear, such as frayed cords or discoloration.

- Replace any damaged power strip immediately to avoid potential safety hazards.

-

Keep Away from Moisture:

- Power strips are not waterproof and should be kept away from liquids.

- Avoid using power strips in damp areas like bathrooms unless they are specifically designed for wet conditions.

-

Positioning:

- Place the power strip on a flat, heat-resistant surface to avoid overheating.

- Avoid covering the strip with rugs, curtains, or other materials that could block ventilation.

7.3 How to Maintain an Organized Workspace

Incorporating power strips into a workspace can sometimes lead to cable clutter. Maintaining an organized setup improves efficiency and aesthetics. Here’s how:

Cable Management Tips

-

Use Adhesive Clips:

- Stick adhesive cable clips to the underside of desks or along walls to guide and organize cables.

- These are ideal for routing charging cables and keeping them accessible.

-

Velcro Ties:

- Bundle cords together using Velcro ties to prevent tangling.

- Adjustable and reusable, these ties are perfect for power cables that frequently change positions.

-

Cable Sleeves:

- Encase multiple wires in a flexible cable sleeve to create a clean, streamlined look.

- These are especially useful for setups with multiple monitors or electronic devices.

Placement of Power Strips

- Mount power strips under the desk or on walls to keep them off the floor and reduce tripping hazards.

- Choose power strips with USB ports to eliminate the need for bulky adapters, further reducing cable clutter.

Table: Essential Tools for Workspace Organization

| Tool | Purpose | Example Usage |

|---|---|---|

| Adhesive Cable Clips | Secures cables to surfaces | Routing phone chargers or USB cords |

| Velcro Ties | Bundles multiple cables together | Organizing power cords |

| Cable Sleeves | Encases multiple wires into a single tube | Simplifying monitor cable setups |

7.4 Common Missteps and How to Avoid Them

-

Using Expired Surge Protectors:

- Surge protectors have a limited lifespan, often based on their joule rating. Over time, their ability to absorb voltage diminishes.

- Replace surge protectors every 3–5 years or sooner if indicated by the device.

-

Daisy-Chaining Power Strips:

- Connecting one power strip to another is highly discouraged and poses significant safety risks.

- Always plug power strips directly into a wall outlet.

-

Ignoring Certification Marks:

- Non-certified power strips may be cheaper but often lack critical safety features.

- Always look for UL, ETL, or CE certifications to ensure product safety and reliability.

7.5 Conclusion: Safer and Smarter Usage

By following these best practices and addressing common concerns, you can enhance the safety, functionality, and organization of your power strip usage. Whether it’s replacing a worn-out surge protector, optimizing cable management, or simply avoiding overloading, these steps contribute to a safer and more efficient environment. Remember, small adjustments in usage can prevent significant risks while improving overall convenience.

Chapter 8: Additional Resources

As we’ve explored the critical aspects of power strips, from safety certifications to best practices, having access to additional resources can empower you to make informed decisions and stay updated on electrical safety. Below are some key organizations and tools to enhance your knowledge and ensure the safe use of power strips and other electrical devices.

8.1 Electrical Safety Foundation International (ESFI)

Overview:

The ESFI is a nonprofit organization dedicated to promoting electrical safety at home and in the workplace. Their comprehensive resources aim to educate the public on how to prevent electrical hazards.

What You’ll Find:

- Home Electrical Safety Guides: Step-by-step instructions on maintaining a safe electrical setup in your home.

- Seasonal Safety Tips: Advice on electrical safety for holidays and weather-specific challenges.

- Workplace Safety Guidelines: Tailored resources for businesses to reduce electrical accidents on-site.

Website: www.esfi.org

8.2 Consumer Product Safety Commission (CPSC)

Overview:

The CPSC is a government agency tasked with protecting the public from unreasonable risks associated with consumer products. They frequently issue recalls and safety updates to address potential hazards.

What You’ll Find:

- Recall Notices: Updates on power strips and surge protectors recalled due to safety defects.

- Educational Materials: Guides and articles on identifying unsafe products and using them correctly.

- Incident Reports: Insights into common causes of electrical accidents and how to avoid them.

Website: www.cpsc.gov

8.3 National Fire Protection Association (NFPA)

Overview:

The NFPA is a global nonprofit organization committed to eliminating fire, electrical, and related hazards. Their work spans education, advocacy, and the development of safety standards.

What You’ll Find:

- Electrical Fire Prevention Tips: Practical advice on reducing fire risks associated with electrical devices.

- Codes and Standards: Information on fire safety regulations for residential and commercial properties.

- Training Programs: Professional development resources for electricians and safety professionals.

Website: www.nfpa.org

8.4 Recommended Tools and Applications

-

CertCheck by UL:

- Purpose: Verify UL-certified products quickly and easily.

- How It Helps: Ensures the power strips you purchase meet safety standards.

-

WattWise Calculator:

- Purpose: A simple tool for calculating the total wattage of devices connected to a power strip.

- How It Helps: Prevents overloading by ensuring your setup remains within safe limits.

-

Smart Home Apps:

- Examples: Apps like Alexa, Google Home, and SmartThings can monitor power usage and alert you to irregularities in connected smart power strips.

- How It Helps: Adds convenience and an extra layer of safety for tech-savvy users.

8.5 Closing Thoughts

Access to reliable information and tools is essential for maintaining a safe and efficient electrical setup. Organizations like the ESFI, CPSC, and NFPA offer valuable insights to help consumers and professionals alike navigate the complexities of electrical safety.

By leveraging these resources, you can stay proactive, minimize risks, and make better decisions when purchasing or using power strips. Remember, a little knowledge can go a long way in ensuring both safety and peace of mind.

Encourage your friends, colleagues, and family to explore these resources and prioritize electrical safety in their homes and workplaces. Together, we can foster a culture of awareness and prevention.

Conclusion

Power strips, often viewed as simple and utilitarian devices, play a pivotal role in modern life, ensuring that our increasingly connected world functions safely and efficiently. Over the course of this thesis, we have explored their fundamental definitions, technical specifications, designs, safety certifications, market dynamics, and best practices for use. Each chapter has highlighted how power strips have evolved from basic tools into sophisticated solutions designed to meet the demands of contemporary households and businesses.

Key Takeaways

-

Understanding and Innovation:

Power strips are no longer just outlets for electricity; they reflect technological progress, incorporating advanced features like surge protection, USB ports, and intelligent power management. The inclusion of safety certifications such as UL, ETL, CE, and RoHS ensures that these products meet stringent standards, protecting users and devices alike. -

Global Perspectives:

Across the world, power strips are adapted to diverse needs and preferences, from different naming conventions like "power boards" and "extension leads" to designs tailored for specific regions. This global diversity reflects the adaptability and universality of power strips. -

Design and Materials:

Thoughtful design, durable materials, and features such as childproof safety gates and optimized socket spacing enhance user experience while ensuring safety. As aesthetic and functional demands grow, manufacturers are incorporating elements that align with modern interiors and lifestyles. -

Future Trends:

The integration of USB-C ports, quick-charge protocols like QC, PD, GS and PPS, and even smart home compatibility are setting the stage for the next generation of power strips. Sustainability and energy efficiency will also drive innovations, aligning with the global push for greener practices. -

Consumer Empowerment:

Through education on certifications, best practices, and product maintenance, consumers are better equipped to make informed decisions. This empowers individuals and organizations to prioritize safety and performance without compromising convenience or cost-effectiveness.

A Look Ahead

As technology continues to evolve, power strips will remain at the forefront of innovation, bridging the gap between traditional electrical systems and the smart, sustainable homes and workplaces of tomorrow. Advances in wireless charging, energy monitoring, and eco-friendly designs are likely to redefine their role in our daily lives, moving beyond functionality to become integral components of modern infrastructure.

Final Thoughts

The journey of power strips, from their earliest forms to the multi-functional devices we use today, is a testament to human ingenuity and adaptability. They remind us that even the simplest tools can have profound impacts when thoughtfully designed and implemented. By understanding their history, technical details, and future potential, we can make safer, more sustainable choices and contribute to a world where technology and responsibility go hand in hand.

Let us take these insights forward, fostering greater awareness and inspiring innovation in a field that touches every aspect of our lives. After all, it is the small things—like power strips—that keep our big ambitions powered up.