Safety Risks of Overcrowded Outlets

Overload Risks

Narrow socket spacing can significantly increase the risk of electrical overload. When multiple devices are plugged into closely spaced outlets, the power strip may be forced to handle more current than it is rated for. This can lead to overheating, short circuits, or even electrical fires. According to UL guidelines, power strips must adhere to specific load ratings and safety standards to prevent such hazards, emphasizing the importance of proper socket spacing to mitigate risks.

Heat Dissipation Issues

Another safety concern with tight outlet spacing is inadequate heat dissipation. Electronic devices generate heat, and when outlets are too close together, the accumulated heat from multiple devices can become trapped. This can damage the power strip and connected devices, increasing the risk of malfunctions or fires. The ETL certification ensures that power strips are designed to handle heat dissipation effectively, which is crucial for maintaining safety.

Efficiency Problems with Tight Spacing

Plug Interference

One of the most common issues with narrow socket spacing is plug interference. When plugs are too close together, one plug can obstruct others, making it difficult to use all outlets effectively. This not only reduces the functionality of the power strip but can also cause physical damage over time. Users frequently report frustration with power strips that cannot accommodate larger adapters or multiple plugs without forcing or rearranging.

Device Compatibility

Compact spacing can limit the compatibility of various plug types and sizes. Devices with large plugs or multiple prongs may not fit properly, forcing users to choose between essential devices or use additional adapters. This problem is particularly evident in environments with diverse electronic equipment, such as offices and workshops. Products that meet UL or ETL standards are designed to accommodate a variety of plug sizes and configurations, improving user experience.

User Experience

Consumer feedback highlights significant dissatisfaction with power strips that suffer from poor socket spacing design. Users often face difficulties with plug placement, resulting in overlapping plugs and limited access to outlets. Addressing these issues can greatly enhance overall user satisfaction and convenience.

Industry Perspective

Manufacturing Standards

In North America, power strips must adhere to strict standards set by organizations such as UL (Underwriters Laboratories) and ETL (Electrical Testing Laboratories). These standards ensure that power strips are safe to use and include minimum spacing requirements between outlets to prevent overload and heat-related issues. However, these minimum spacing requirements may not always accommodate the wide variety of plug sizes used in practice, leading to potential issues during actual use. Manufacturers can address this problem by designing power strips with slightly larger spacing between outlets to better suit different plug sizes, thereby improving functionality and safety.

Recommendations for Improvement

To address these challenges, industry buyers and manufacturers should prioritize products that not only comply with UL or ETL standards but also consider practical usage scenarios. Investing in power strips with thoughtfully designed outlet spacing can enhance both safety and user satisfaction. Collaboration between buyers, designers, and manufacturers to fine-tune these design elements will ensure that products meet both regulatory standards and practical needs, leading to improved overall product quality.

Consumer Recommendations

Choosing the Right Power Strip

When selecting a power strip, consider the following factors to ensure optimal performance:

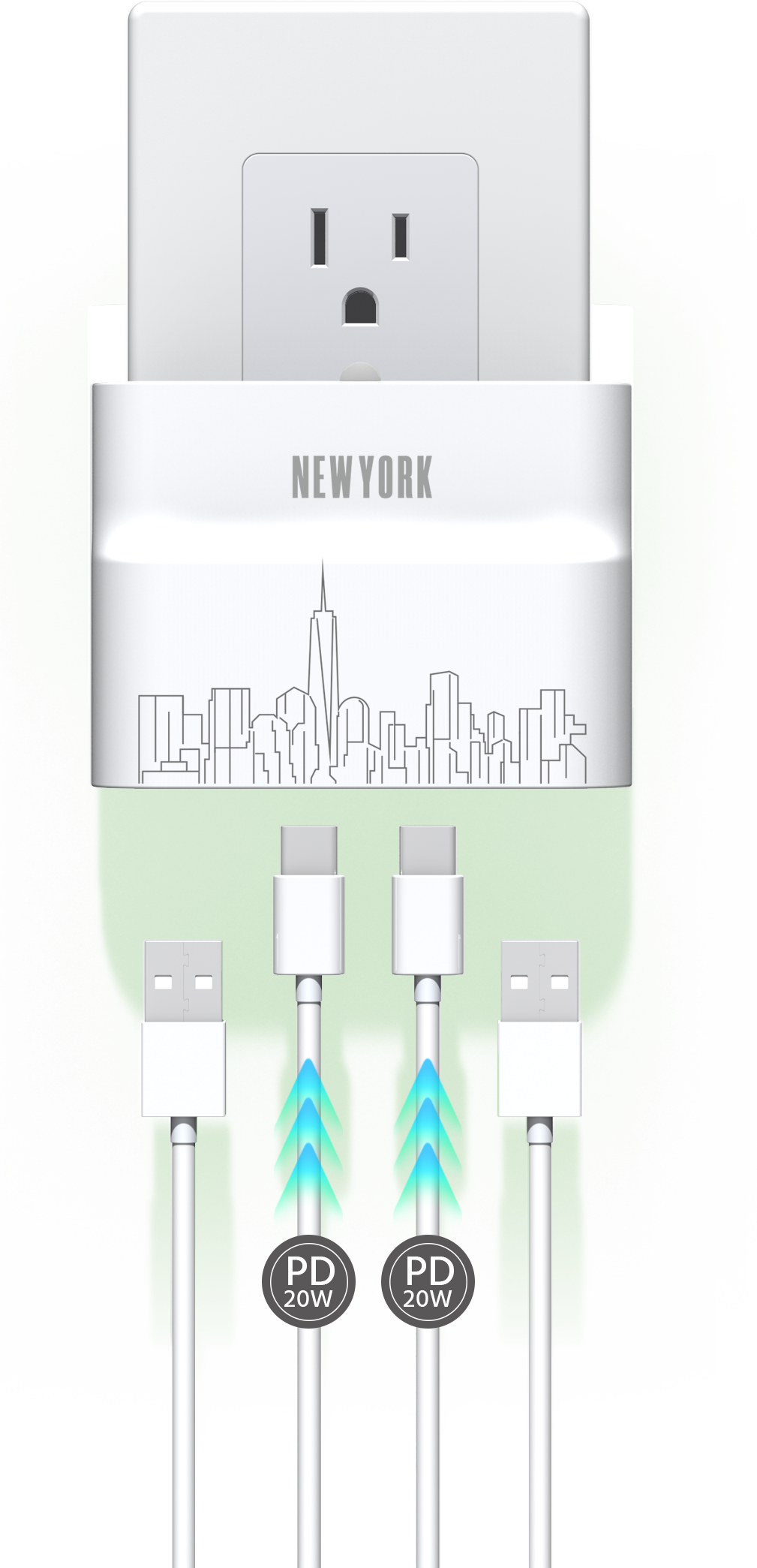

- Socket Spacing: Choose power strips with adequate spacing between outlets to accommodate various plug sizes and prevent interference.

- Certification: Opt for products that meet UL or ETL certification to ensure they adhere to safety and performance standards.

- Design Features: Look for power strips with additional features such as surge protection and individual switches for each outlet to enhance both safety and functionality.

Maintenance Tips

Proper use and maintenance of power strips can extend their lifespan and ensure safe operation. Avoid overloading, keep the power strip in a well-ventilated area, and regularly inspect it for signs of damage or wear.

Conclusion

The issue of socket spacing on power strips is a significant factor affecting both safety and efficiency. By understanding the implications of overcrowded outlets and making informed choices, consumers and industry buyers can enhance their power management practices. For more information on high-quality power strips that meet UL or ETL standards, visit our product page.

Prioritizing proper design and adherence to industry standards ensures a safer and more efficient electrical environment, protecting both devices and users.